Digital Intelligence Qianchuan | Multi-category Informatization Customizes the Perfect Home for Users

Driven by both the times and the industry, the traditional home furnishing industry is undergoing unprecedented transformation and reshaping. Facing diversified market demands and consumers' continuous pursuit of quality life, only by stepping out of the comfort zone of traditional models, achieving digital transformation and upgrading, and seeking new development models can greater market opportunities be obtained and innovative growth realized. Against this backdrop, Qianchuan Whole Home Customization continuously explores and practices digital and intelligent transformation, using intelligent manufacturing as the engine to embark on the path of multi-category digital and information transformation and upgrading.

01/

Diversified Layout

Injecting Strong New Momentum

With its strong R&D, manufacturing, and sales capabilities, Qianchuan Whole Home Customization covers multiple fields including wooden doors, wardrobes and kitchen cabinets, wall panels, fire doors, system doors and windows, and whole home customization, building a multi-category matrix of fully furnished home products and forming a diversified industrial pattern.

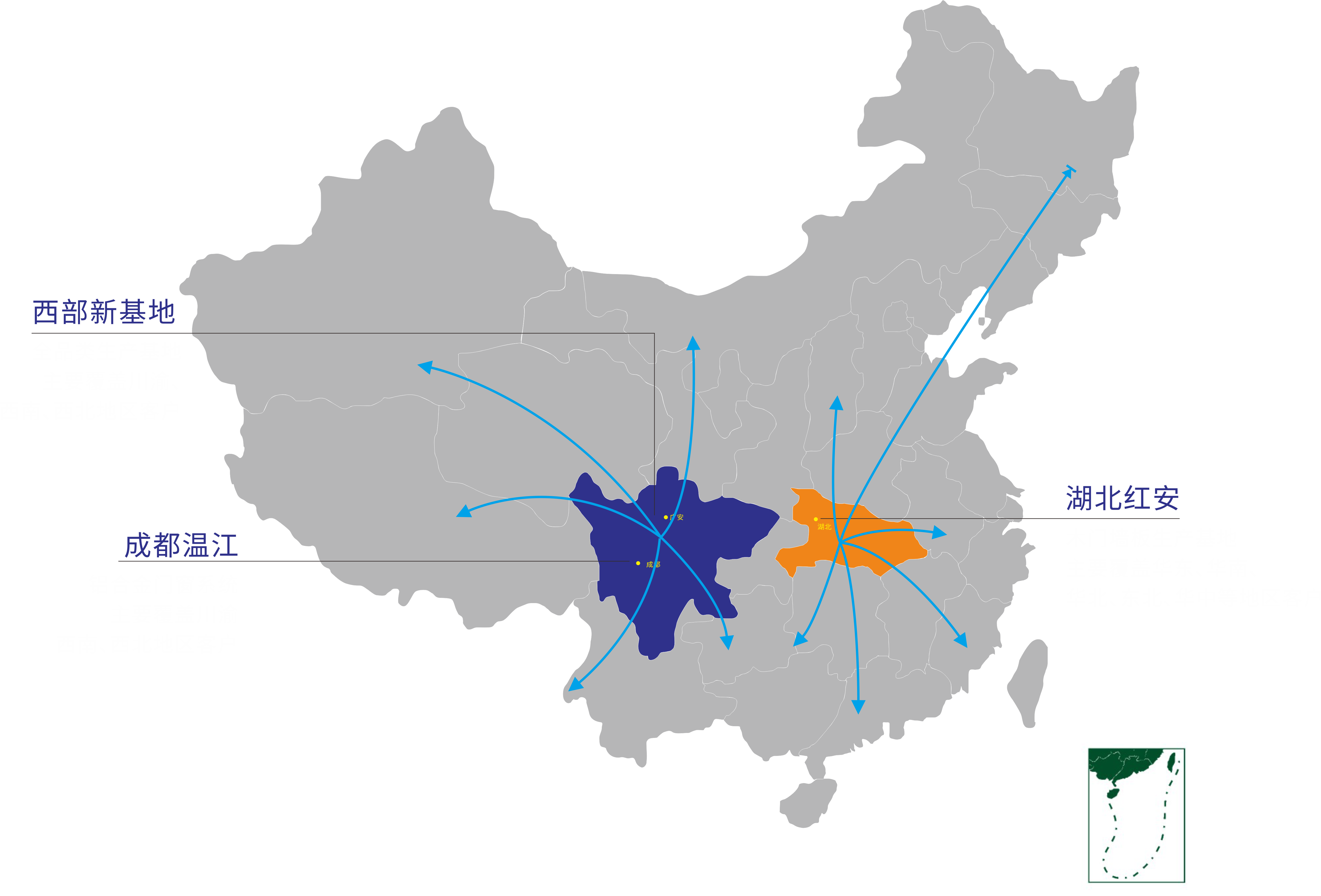

To better meet market demands, Qianchuan Whole Home Customization continuously expands its production scale, currently owning three intelligent production bases in Chengdu, Hubei, and Guangyuan, covering a total area of 950 acres with a total construction area exceeding 450,000 square meters. After the full completion of the new Guangyuan base, the annual production capacity will reach 1.8 million wooden doors, 1.2 million square meters of whole home customization, 360,000 square meters of wall panels, and 200,000 square meters of system doors and windows, injecting strong momentum for the continuous growth of Qianchuan Whole Home Customization's business.

02/

Integration of Front-end and Back-end Data

Building a Full-process Intelligent Factory

In the wave of digital transformation, Qianchuan Whole Home Customization actively embraces new technologies to build a full-process intelligent factory. Since fully transforming into whole home customization in 2023, multiple sets of industry-leading information systems have been deployed to achieve full-process connectivity from front-end design to back-end production.

Front-end dealer stores use the "Kujiale" platform for 3D modeling and previewing whole home customization renderings, providing customers with a more intuitive design display. After receiving orders, the "OMS Order Management System" quickly transmits order information to the factory side. The back-end uses the "ZhiMu Order Splitting System" for precise order splitting and automatic quoting, then the "MES Production Management System" arranges production. Completed orders are scanned, packaged, and warehoused, with inbound and outbound management handled by the "WMS Warehouse Management System." The entire order process can be tracked in real-time through the "OMS Order Management System." Data interfaces between front-end and back-end information systems are connected, realizing digital business and intelligent production for Qianchuan Whole Home Customization from store design to delivery and installation.

03/

Industrial Automation Empowerment

Precisely Achieving Whole Home Customization

To precisely meet consumers' needs for whole home furniture customization and create a more personalized, high-quality home life, Qianchuan Whole Home Customization has introduced flexible intelligent production lines integrating processes such as cutting, edging, drilling, sorting, and packaging, achieving a complete intelligent manufacturing process from raw materials to processing to finished products.

The intelligent cutting system automatically labels, feeds, and cuts board shapes and sizes accurately according to order data; PUR technology is used for intelligent edging to enhance product aesthetics and durability; the most advanced domestic dual-station through-type six-sided drilling processing center automatically completes drilling and grooving operations by scanning and identifying board information, ensuring processing accuracy. In sorting and packaging, the application of information systems enables efficient classification, organization, and packaging of boards, further improving production efficiency and product quality.

Through in-depth practice of digital transformation and intelligent manufacturing, Qianchuan Whole Home Customization has not only achieved dual improvements in production efficiency and product quality but also built an omnichannel layout and high-standard quality control system, laying a solid foundation for sustainable development. Qianchuan Whole Home Customization will further explore more dimensions of innovation, comprehensively promote enterprise informatization, provide strong momentum for digital and intelligent development, and help lead the home furnishing industry toward high-quality development.

-END-

Chengdu

Chengdu